Blasting is a vital surface preparation process that helps to remove rust, scale, and old coatings. It also prepares the surface for optimal powder coating adhesion.

When properly designed, blast rooms are critical to surface preparation processes. They provide a controlled and safe environment for abrasive blasting, ensuring optimal results every time.

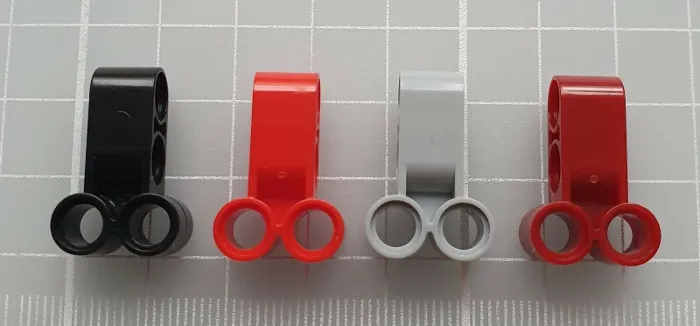

Abrasive Media

Abrasive blasting removes unwanted deposits, prepares surfaces for coating, or alters their shape. The process is often used with other surface treatments to achieve the best results.

Blasting with abrasive media can be carried out in portable blast equipment or blast rooms. Each method uses different abrasive media and blasting parameters such as pressure, nozzle distance, and media type to achieve optimum results.

Wet abrasive blasting is another option that uses water as a fuel, lubricating the media to reduce dust and speed up the cleaning process. It is also much safer for siliceous materials and hazardous substances like asbestos.

One of the most critical components of a blast room is a media reclaim system that allows abrasive to be recycled. These systems can range from simple “sweep-in” designs to entire floor reclaims, minimizing purchase and disposal costs.

Dust Collection

Blasting rooms use dust collection tools to remove airborne debris and keep the work environment safe. They are essential to ensuring visibility and healthy, breathable air for blasting operators while reducing respiratory hazards.

Abrasive blasting produces a large amount of respirable dust that can be toxic and dangerous to workers if inhaled into the lungs. This can lead to serious health complications and reduce productivity.

To mitigate these issues, a high-quality filtering system can be installed in the blast room to capture all hazardous dust before it escapes into the environment. This can help prevent employees’ exposure to harmful contaminants such as crystalline silica and lead that can cause respiratory ailments, damage skin or eyes, and even cause cancer.

Safety

A blast room, a wholly enclosed abrasive blasting enclosure, eliminates the safety hazards of outdoor abrasive blasting and reduces cleaning and disposal costs. An adequately designed blast room includes abrasive recovery systems, ventilation, lighting, and a dust collection system.

Blast rooms also provide a safe environment for workers, as they are equipped with heavy-duty protective gear and face/head shields. It is essential to keep all other workers away from the abrasive area and ensure that employees have adequate breathing equipment and clean hands.

Many dry blasting operations create dust clouds that can travel across the job site and into the work zone of other workers. It is vital for all employees to wear clean, breathable clothing and to change their respiratory masks often.

A dust collection system is essential in any abrasive blasting operation. It moves and filters the airborne dust created during the abrasive recovery process, maintains visibility for the operator, and helps maintain compliance.

Environmental Impact

Abrasive blasting can be an effective way to remove rust and deburr metal surfaces. It can also prepare a metal surface for applying a high-performance coating.

Many abrasive blasting facilities use environmental regulations and other techniques to combat this issue to reduce dust emissions released into the atmosphere. These include abrasive recovery systems and ventilation techniques.

An excellent abrasive blast room can be vital to your business’s efficiency and safety. It should be equipped with abrasive reclaim and recovery systems, dust collection, and ventilation to ensure that the blasting process is effective and that your employees are protected. This will help you to meet environmental regulations and improve your productivity.