If you have to ship products that need to stay frozen or refrigerated, ice packs can help. They are also great for maintaining cold temperatures in coolers.

Dry ice is widespread for shipping perishable items because it doesn’t melt. However, it must be shipped in an airtight container so the carbon dioxide can be off-gas.

Cold Chain Management

The cold chain is a logistics process for products that need refrigeration during shipping. It includes pharmaceutical products, food, and even military supplies. If these products are kept cool, they may spoil during shipping and be rendered functional. It leads to waste and loss of money for the product manufacturer and shipper.

Cold chain management involves insulated shipping containers, plastic liners, and other cooling technologies that keep temperature-sensitive goods frozen or chilled throughout the transport cycle. Additionally, tracking devices are attached to containers to provide the product shipper and carrier with location data throughout the shipment. It allows the container to be tracked through a port, on a rail car, or across the ocean in a ship.

Many companies that ship temperature-sensitive goods opt to use ice packs for shipping in combination with dry ice or other coolers, depending on the specific needs of their customers. Gel ice packs, for example, melt more slowly than water ice and are ideal for food shippers who need to maintain the cold temperature of their products for a few days or more. They also don’t evaporate as rapidly as dry ice, so they can be reused by both the shipper and the package recipient. However, it’s essential to warn the recipient that it contains dry ice so they don’t inhale it.

Biopharmaceutical Products

Biopharmaceutical products are created from living cells, bacteria, or other organisms that can easily be damaged or contaminated by environmental factors such as temperature changes or moisture exposure. Unlike pharmaceuticals manufactured from chemicals, biologics have a higher price tag and require extra care during packaging to ensure they don’t suffer damage or contamination. Fortunately, packaging solutions can help regulate the environment and maintain the proper temperatures throughout the shipping and storage.

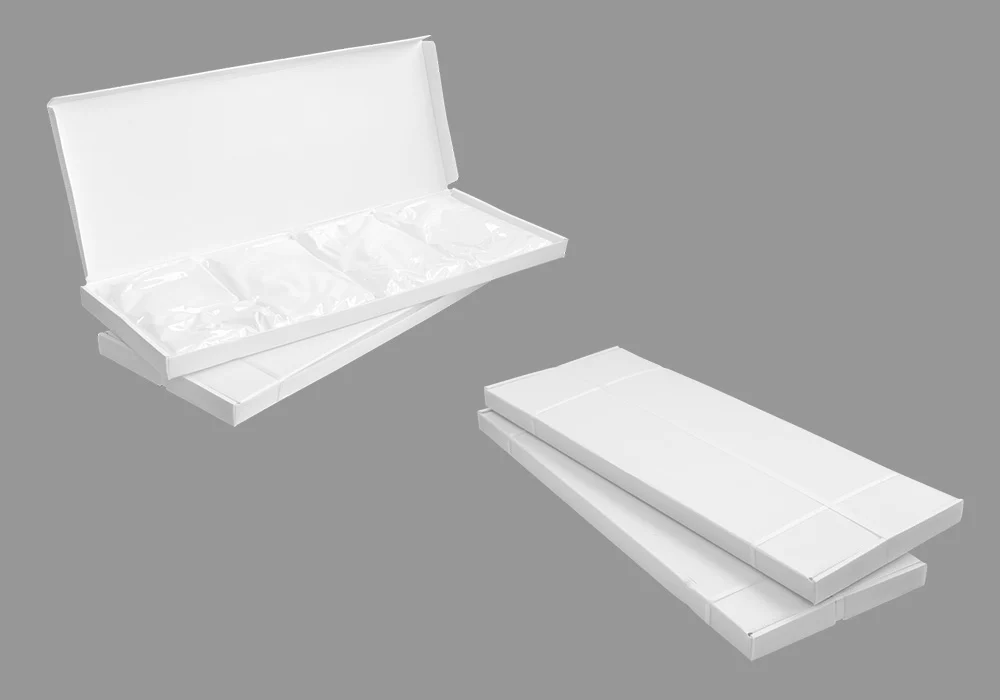

These flexible packs are insulating, can be reused multiple times, and come with premium exterior wrapping materials.

Controlled Room Temperature (CRT) Drugs

Companies within healthcare industries store a large variety of products, such as medicine, blood samples, and vaccinations. Many drugs are subject to strict temperature storage requirements and must be stored per manufacturer guidelines and USP general chapter 1079. These regulations require that these sensitive drugs be kept at stable temperatures, even during shipping, to maintain product potency and quality.

Temperature fluctuations during transportation can damage the integrity of these delicate pharmaceuticals, resulting in product loss and potential regulatory violations. Insulated shipping containers are required to prevent temperature excursions and provide consistent thermal protection with an active cooling system. These active cooling systems use phase change materials to reverse and warm the container, maintaining consistent temperature levels throughout transit without needing external energy sources.

Current Supply Chain

When perishable products such as foods and biomedical supplies must be shipped, they must be maintained at a specific temperature. Many companies use dry ice or gel packs to cool their goods during transit. While both are effective, knowing which cooling method suits your company’s needs is essential.

The best way to determine which cooling solution is best for your product depends on what you’re shipping and how long the shipment will be in transit. For example, if you’re shipping meat that needs to be kept cold, a reusable gel pack may be more appropriate than dry ice. These ice packs are made of poly bags filled with water or a gel refrigerant. They freeze and thaw at a similar rate as water, making them ideal for preserving food and other items that require temperature control during transit.

Another benefit of reusable gel packs is that they’re non-toxic and safer for handling than dry ice, which can damage skin and require special training to handle appropriately. Most of these ice packs are designed as small, wallet-sized pouches that can be used to keep food and drinks cold. The gel inside them is made of propylene glycol, an organic compound similar to antifreeze. They are free of harmful chemicals and safe to pour down household drains or septic systems. Additionally, the outer bag is recyclable curbside.